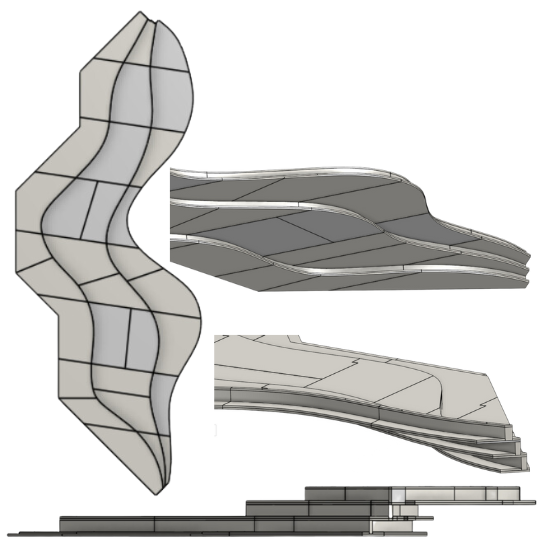

Arched cornice with steps

Gypsum product advantages

The arched cornice with steps is a wavy ceiling cascade with 3 LED noses to achieve lighting and spatial effects and reduce acoustic echo. The waves running on the ceiling run irregularly and have a spectacular effect. All plaster surfaces are made of double plasterboard. Product dimensions and material selection according to wishes

Properties. The product has similar properties to gypsum board, except for the areas that have been machined and glued.

Usage. The product is intended for use in rooms with a relative humidity of no more than 70%. The maximum installation temperature is 50°C. Normal room temperature is recommended for installation

Installation

⇒ The corresponding technical solutions have been provided by the construction project developer for installation on construction sites

⇒ It is recommended to install the product on a stone, frame, wood or plaster surface using a wooden or metal frame. If the shape of the product and the profile of the nearby surface allow it, the product can be properly attached to it

⇒ It is recommended to use either wooden material or a metal frame to connect the products together, which connects both halves of the product together in such a way that cracks do not form at the joints after finishing

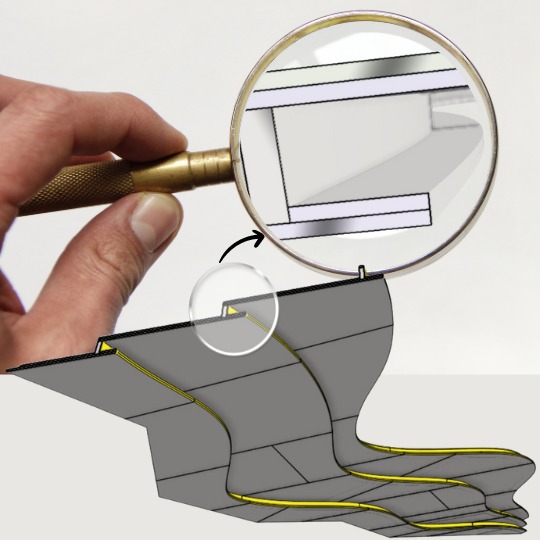

Fixing. In sparse areas of the product (e.g. glued surfaces and gaps associated with sawing and milling), it is recommended to use adhesive foam or adhesive sealant instead of screw connections. The requirements for screwing the product are described in the plasterboard installation instructions

Cutting. Cutting double-layer plasterboard to size is different from cutting single-layer plasterboard

⇒ When cutting a single part of the product, mark the cutting line (straight or cutting angle) with a laser

⇒ Saw the product to size with a hand saw. Sawing must be done carefully – a blunt saw, large saw teeth and placing the product on a base can cause the product to break in an undesirable place

Finishing. Similar to finishing drywall

Filling joints. Similar to filling drywall joints, if necessary, chamfers can be cut into the edges of the product to accommodate a sufficient amount of sealant or joint filler

Storage. Products should be stored on a smooth surface, preferably on a pallet. Protect products from moisture

Transportation on the construction site

⇒ The product must be transported properly supported and carefully – high tensile pressure can cause the glued surface to come loose

⇒ If there is a risk that the product will be damaged during transport, additional covers or additional fastenings must be used

⇒ It is recommended to transport long or heavy parts with two people and with two hands

⇒ The internal support blocks and fastening tape of the parts are removed (if necessary) immediately before installation

Curved screen with steps, manufacturing information

⇒ Two-layer plasterboard, material selection according to the customer’s wishes, the specified external (v) and internal dimensions (s) are used

⇒ The wavy vertical surface is made of double-layer rolled plaster, between which a painting fabric is glued

⇒ PUR glue D4, 1-component, adheres well to the cut plaster edge

⇒ Individual parts and supports of the product cut with CNC to maintain the shape during gluing and transportation

⇒ Tape to fix the shape of the product during gluing and transport

| Weight | 326 kg |

|---|---|

| Dimensions | 8150 × 3290 × 300 mm |

| Plasterboard | 2x standard gypsum (16.2 kg/m2) |

| Finish | none |

| Sound | 20 dB |

| Fire | 30 min |

| Materials | PUR glue |

| Author | Kipsik |

| Manufacturer | Kipsik OÜ |

| Origin | Estonia |