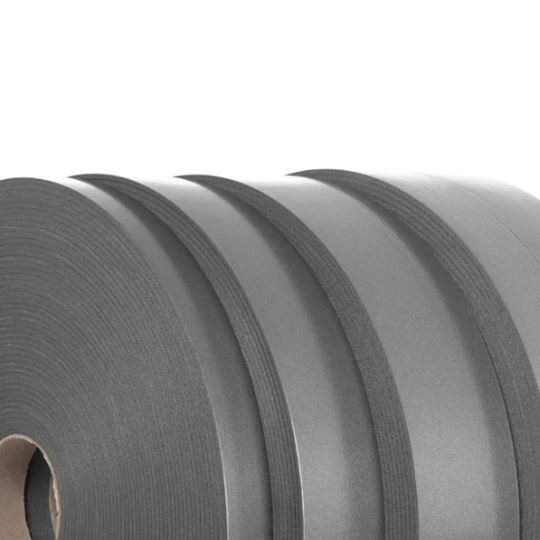

Frame seal PE, self-adhesive

Self-expanding polyurethane seal

13.00 € Includes VAT

| Quantity | Discount | Discounted price |

| 1 | - | 13.00 € |

| 2 - 5 | 2.5% | 12.68 € |

| 6 - 10 | 5% | 12.35 € |

| 11 + | 7.5% | 12.03 € |

Hinnad sisaldavad käibemaksu

Frame Seal PE, self-adhesive – a polyethylene-based, self-adhesive, elastic, single-sided adhesive, waterproof, closed-cell polyethylene strip with good adhesion and easy installation. The thickness and width of the seal are customized according to the customer’s request

Properties. Sound-insulating and elastic. Underside reinforced with adhesive tape backed by fiberglass mesh. Expands through diffusion, forming a weatherproof seal. Minimizes the risk of mold and rot on contact surfaces. UV-resistant and allows joints to breathe

Applications:

⇒ In the construction of lightweight partition walls from gypsum board on metal frames

⇒ For sealing and sound insulation between various other construction elements

⇒ For insulation between facade panel materials and wooden or metal frames, including in plinth areas and during sandwich panel installation

⇒ For lighter glazing applications

⇒ For sealing wall modules: improves acoustics and thermal insulation

Installation:

⇒ Surfaces to be sealed/connected must be clean, dry, and square

⇒ It is recommended to select the seal dimensions according to the data provided below to achieve the required joint tightness. Possible structural displacements should also be taken into account

⇒ When continuing the seal, the ends must be pressed together; overlapping of seals should be avoided

⇒ Recommended installation temperature: +5 °C to +40 °C. The seal should be stored at room temperature

⇒ Do not clean with pressure or strongly acidic solutions!

Sealing strip dimensions Length: 25,000 mm (25 meters), width: 35 mm. Thickness: 2 mm

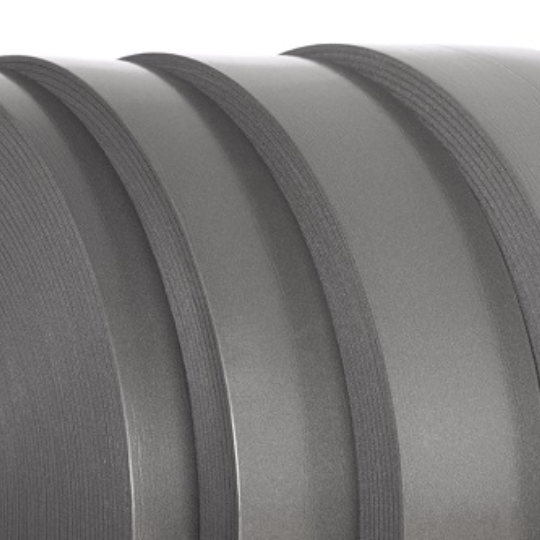

Color. Black (anthracite grey)

Material Elastic closed-cell polyethylene foam, coated on the underside with high-adhesion synthetic rubber adhesive (hot-melt), and covered on the top side with a protective, non-removable silicone foil

Roll Quantity : 25 m with 2 mm thickness

Frame Seal PE (Self-Adhesive), Technical Specifications:

⇒ Density approx. 30 kg/m³, according to ISO 845

⇒ Water absorption < 1%

⇒ Highly resistant to high humidity

⇒ Temperature resistance: –30 °C to +80 °C

⇒ Materjali tõmbetugevus pikisuunas 325 kPa, ristisuunas 220 kPa, ISO 1926

⇒ Compressive strength at 50% deformation: 98 kPa, according to ISO 844

⇒ Material compression: 12% (at 23 °C; 22 h; 25% compression; measured after 24 h), 20% (measured after 0.5 h), according to ISO 1856-B

| Weight | 0.3 kg |

|---|---|

| Dimensions | 25000 × 35 × 2 mm |

| Plasterboard | none |

| Finish | none |

| Sound | 0.3s 500Hz |

| Materials | PE |

| Seal | 3×35 mm, PE, self-adhesive |

| Author | Kipsik |

| Manufacturer | Fixus Trade |

| Origin | France |

You may be interested in…

551.75 € Original price was: 551.75 €.525.00 €Current price is: 525.00 €. Includes VAT

13.00 € Includes VAT